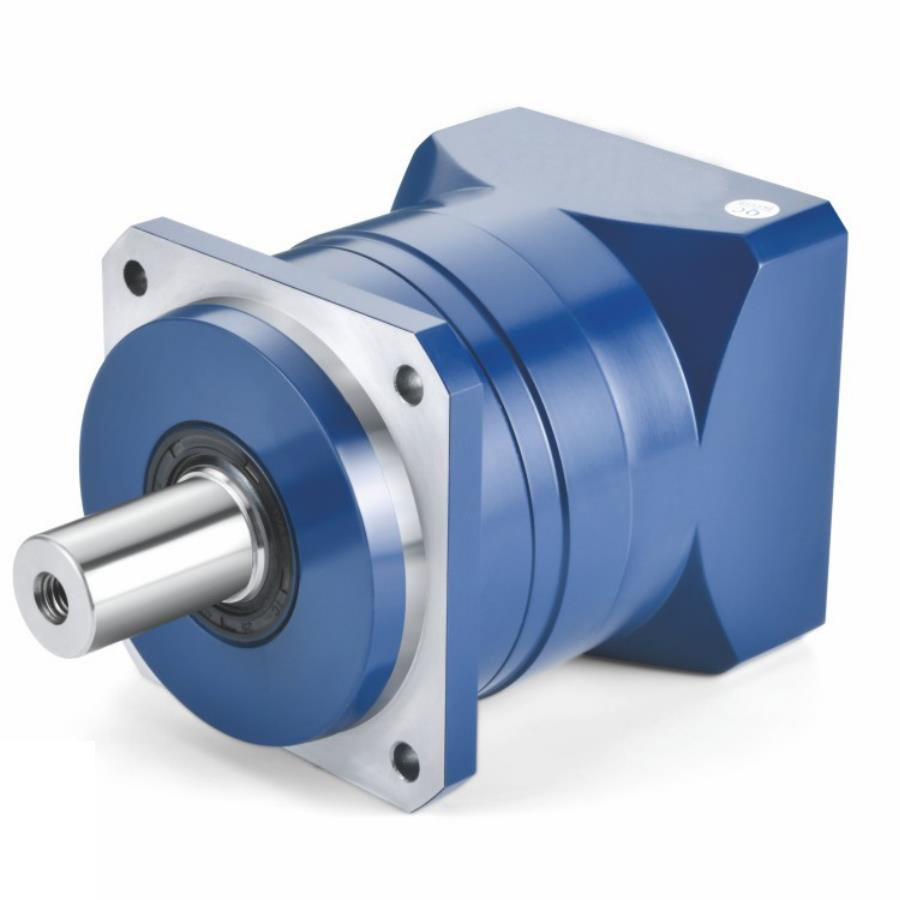

The safety factor, also known as the service factor, of a planetary reducer is mainly obtained by dividing the rated power of the reducer by the power of the motor. The safety factor of the reducer is very important, as it can directly determine the normal operation of subsequent equipment. So, how to determine the safety factor of a planetary gearbox?

The safety factor of a planetary reducer refers to the value factor of the reducer determined based on actual working conditions and mechanical factors of the driven part when selecting the reducer, in order to ensure that there is a surplus of rated mechanical and thermal energy of the reducer. The main influencing factors include operating time, load, also known as "load" situation, etc.

The safety factor of planetary reducers should have sufficient load-bearing capacity. At present, although there are recognized (standard) calculation methods for tooth surface, tooth root, and adhesive bearing capacity, it is difficult for an ordinary engineer who is just starting to design gear transmission to successfully complete the design of gear transmission. When calculating the load-bearing capacity of planetary reducers, an appropriate safety factor is important. If the safety factor is too large, it will increase the size, weight, and cost. But if the safety factor is too small, it can cause unexpected failures and dangers. The safety factor should be within a reasonable range and meet the requirements of the equipment.

Cheng Shen Precision Machinery (Shanghai) Co., Ltd.

Cheng Shen Precision Machinery (Shanghai) Co., Ltd.