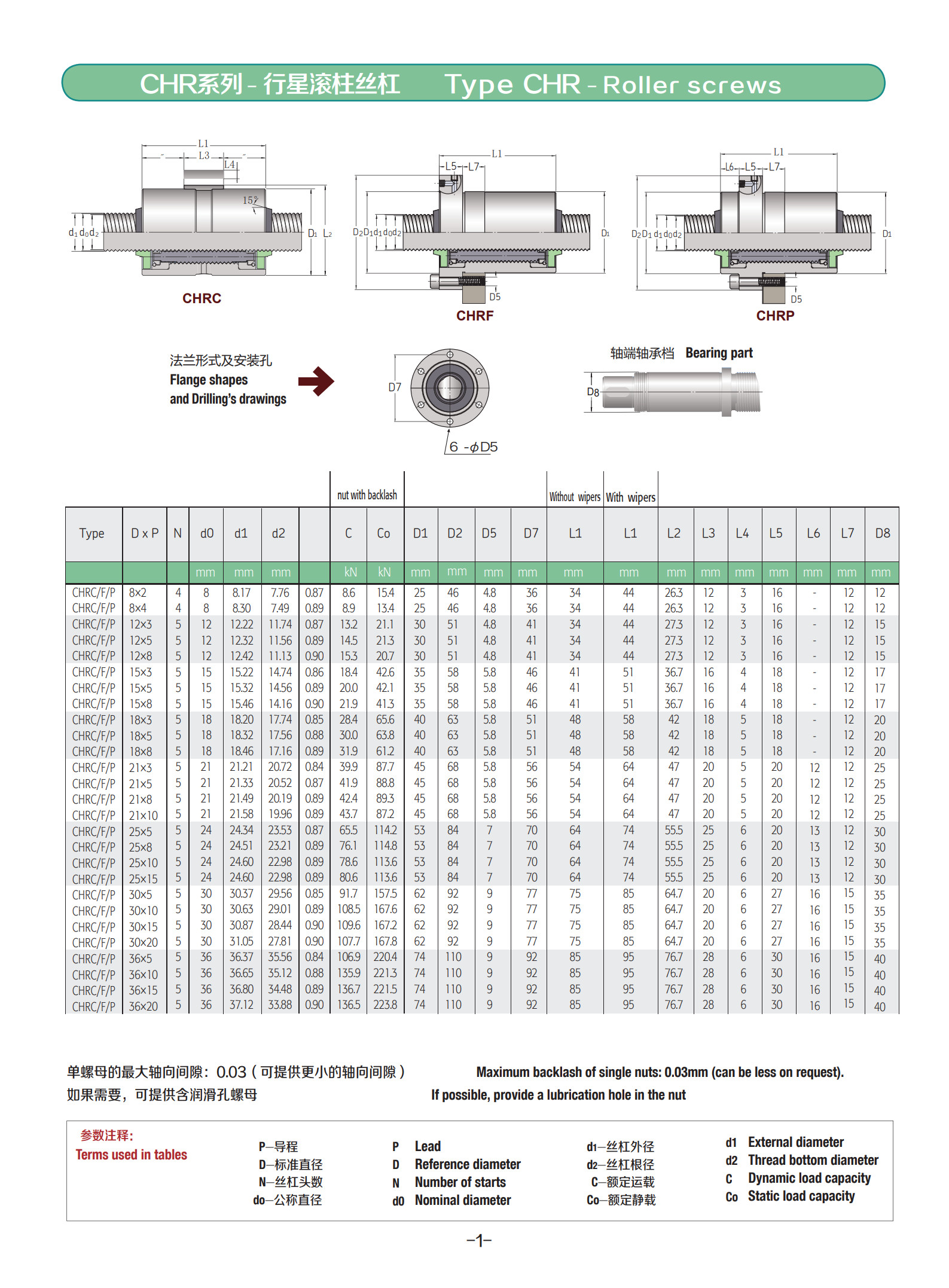

The planetary roller screw is mainly composed of the outer planetary gear, the inner roller screw and the ball.

Outer planet gear: it is the core of the planetary roller screw, consisting of planet gear, inner ring, outer ring and planet shaft. The planetary gear is divided into internal gear and external gear. The internal gear is embedded in the external gear, and the planetary shaft connects the internal gear with the external gear.

Inner cylindrical roller screw: another core component, consisting of ball screw, housing and stop ring. The inner diameter of the ball screw is equal to the outer diameter of the planetary shaft, and the rotating motion is converted into linear motion by rolling the ball on the thread belt.

operational principle

The working principle of planetary roller screw is similar to that of ordinary ball screw. The ball is used to roll on the thread belt and convert the rotational motion into linear motion. However, the working principle of planetary roller screw is more complicated, and its basic principle can be summarized as follows:

The rotational motion of the planetary shaft distributes torque through the planetary gears to multiple teeth.

The teeth of the planetary gear mesh with the teeth of the inner ring, thus transmitting torque to multiple teeth, increasing the stability and accuracy of the transmission.

With the rotation of the planetary shaft, the ball embedded in the planetary gear will roll along the raceway of the planetary shaft and transmit torque to the ball screw to produce linear motion.

The rotation of the planetary shaft will also drive the ball to roll on the thread belt of the ball screw, so as to achieve high-precision linear motion.

Importance of lubrication

Good lubrication is the key to ensure the service life and customer experience of planetary roller screw. As the thread roller of the planetary roller screw has many close contact lines, the friction coefficient of the lubricating grease must be low to ensure high accuracy in the process of frequent commutation. Bithenu W GREASE-97/FR is a proven planetary roller screw lubricant with ultra-low friction coefficient and shear stability to provide stable torque.

summary

Planetary roller screw is characterized by high transmission efficiency, high bearing capacity and high precision, which is suitable for engineering application requiring high precision and high load. Meanwhile, its compact and simple structure makes it easy to install and maintain. Good lubrication is the key to ensure its performance, and it is very important to select proper lubricating grease.

Catalog Download Links

Planetary roller screw

Cheng Shen Precision Machinery (Shanghai) Co., Ltd.

Cheng Shen Precision Machinery (Shanghai) Co., Ltd.