RV reducer, short for Rotary Vector gearbox, is a new hybrid of traditional cycloidal pinwheel and planetary gear transmission devices. It not only overcomes the shortcomings of general pin pendulum transmission, but also becomes the core component of joint drive on industrial robots (especially medium and large industrial robots) with the development of market and technology.

Therefore, RV reducers are also known as precision cycloidal pinwheel reducers, and the common RV reducers in Chuanming are RV-E series and RV-C series. The working principle is that when the input shaft rotates one revolution with an eccentric sleeve, due to the characteristics of the tooth profile curve on the cycloidal gear and its restriction by the needle teeth, the motion component of the cycloidal gear has both orbital and rotational plane motion. When the input shaft rotates one revolution, the eccentric sleeve also rotates one revolution, and the cycloidal gear rotates one tooth in the opposite direction to obtain deceleration. With the help of the W output mechanism, the low-speed rotational motion of the cycloidal gear is transmitted to the output shaft through the pin shaft, thereby obtaining a lower output speed.

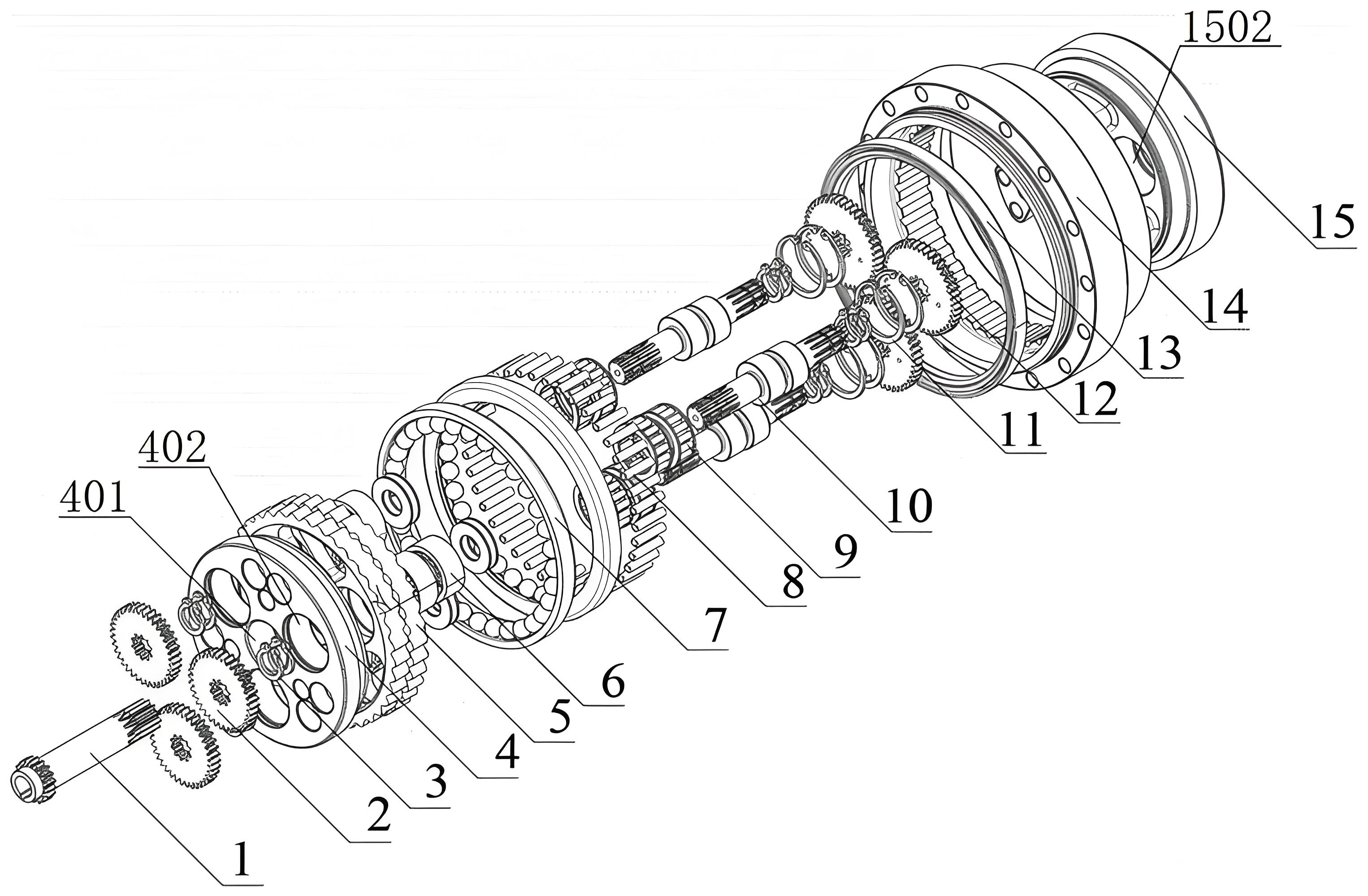

The structure of RV cycloidal pinwheel reducer consists of output flange, support flange, pinwheel housing, cycloidal gear, crankshaft, planetary gear, pinwheel, input gear (optional), main bearing, tapered roller bearing, needle roller bearing with cage, oil seal, etc.

The product features of RV precision reducer are as follows:

1、 The ultra flat design/compact structure is composed of two parts: the involute cylindrical gear planetary reduction mechanism and the cycloidal pinwheel planetary mechanism, achieving an ultra flat shape and contributing to the compact size of the equipment.

2、 High precision is achieved through precision cycloidal gears.

3、 High rigidity improves the meshing rate and disperses the load, resulting in extremely high rigidity.

4、 Efficient setting of appropriate pressure angles to achieve smooth and efficient movements.

5、 The torsional stiffness is high, and the output mechanism is a planetary carrier supported at both ends. The rigid large disk on the left end of the planetary carrier is used for output, and the large disk is connected to the working mechanism with bolts. Its torque stiffness is much higher than that of the output mechanism of a general cycloidal pinwheel planetary reducer. At rated torque, the elastic hysteresis is small.

6、 By optimizing the configuration of gaps in various parts, low back clearance can achieve high-precision positioning with a back clearance of less than 1arcmin.

7、 The installation of the motor is simple and can be carried out using an RV reducer. Users can design according to the installation dimensions of the purchased motor.

RV cycloidal pinwheel reducer adopts cycloidal pinwheel meshing and planetary transmission principle, so it is usually called planetary cycloidal reducer. It is widely used in industries such as petroleum, chemical, transportation, food, medicine, ore, construction, lifting, food, printing, textile, cement, environmental protection, metallurgy, power generation, construction, etc., and has been widely welcomed by large users.

Cheng Shen Precision Machinery (Shanghai) Co., Ltd.

Cheng Shen Precision Machinery (Shanghai) Co., Ltd.